Introducing Laundry's Connected Platform

We’ve spent the past couple years refining, expanding, and enhancing our platform.

Schedule time to visit booth #3211 at the Clean Show

Laundry's Robot Integrator

Automation is no longer a luxury: it’s a necessity.

Spindle Robotics helps laundries overcome rising labor costs and staffing shortages with intelligent, laundry-specific automation that’s easy to implement and built to scale.

Our solutions aren’t picked off the shelf from a distributor. They’re the result of rigorous research, development, and deep industry insight.

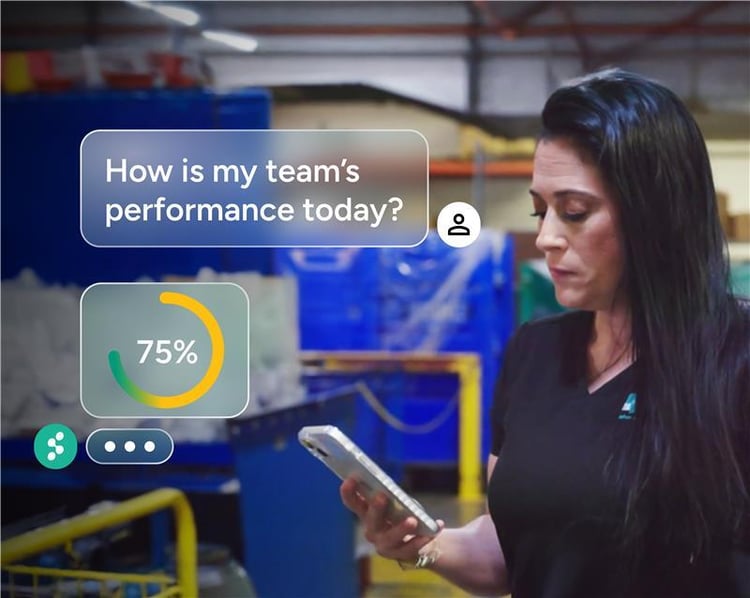

Laundry’s Domain-Specific LLM

Spindle Intelligence is built to sit seamlessly on top of Spindle Core and turn raw data into real-time, actionable insight.

With our domain-specific large language model (LLM), operators can ask natural-language questions such as:

- Who has logged into work today?

- Where are we losing the most labor hours today?

- How has ironer 1 performed over the last month?

No complex dashboards. No IT background required. Just fast, focused answers to the questions that matter most...so you can stay ahead of problems, not react to them.

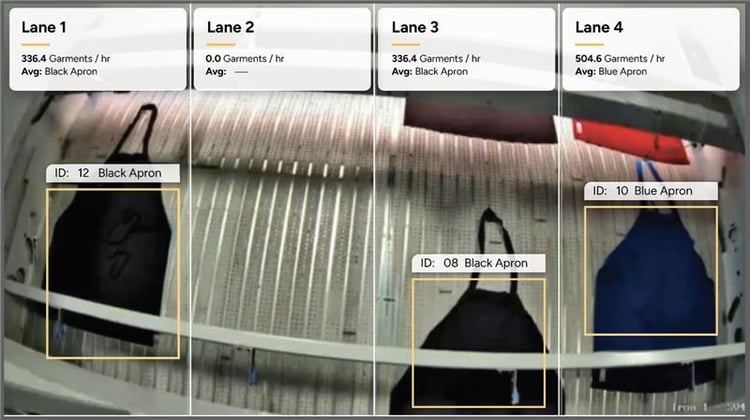

AI-Powered Vision. Smarter Laundry.

For continuous, real-time visibility across your plant floor.

Spindle Vision removes friction from daily operations while elevating safety, accountability, and performance.

With Spindle Vision, you can:

- Improve the user experience for both operators and supervisors.

- Monitor hard-to-measure areas with precision.

- Seamlessly integrate into your existing workflows.

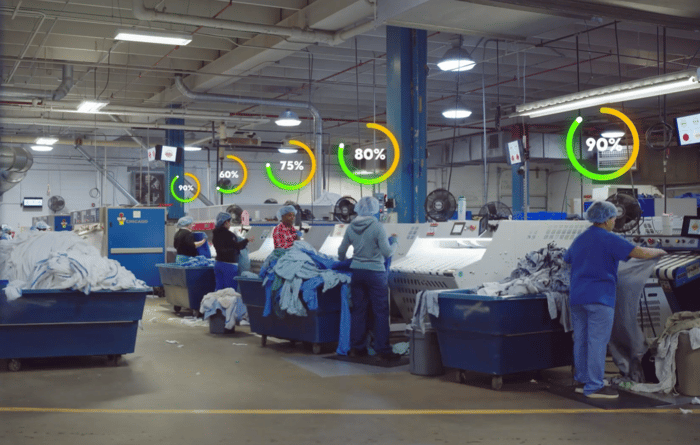

Connecting Data. Powering Performance.

From soil sort to pack-out, Spindle connects the data in real-time from production, maintenance, utilities, and more into a single, streamlined platform.

When your data works together, your team performs better. Every shift. Every day.

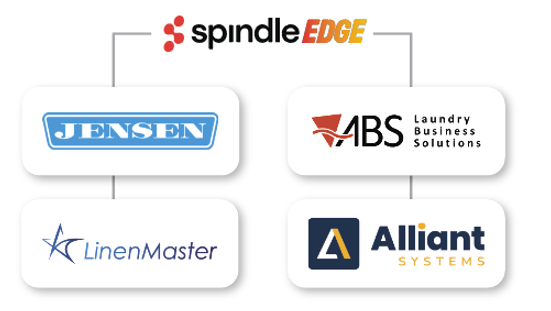

Introducing Spindle Edge: Unlock the Power of Shared Data

The Spindle Edge Program is a new initiative by Spindle and industry partners designed to enhance data experiences for commercial laundry customers by fostering direct data sharing between various industry vendors and Spindle's Ops management platform.

Connect Your Operations on the Spindle Platform

Spindle is the industry's leading connected operations platform built specifically for commercial laundries—bringing together data from your workforce, equipment, utilities, maintenance systems, and even third-party vendors.

By centralizing this critical information into one intuitive platform, Spindle helps teams make faster, smarter decisions. Whether you're tracking productivity, monitoring equipment health, managing energy use, or coordinating across departments, Spindle gives you complete visibility and control across your entire plant—turning siloed operations into a synchronized system.