Unplanned Equipment Downtime Ends Here.

Unplanned downtime due to equipment failure is incredibly disruptive and expensive.

With Spindle CMMS, you’re always in the know about your equipment’s maintenance status and schedule. That way, you can proactively say goodbye to equipment failure surprises.

CMMS Designed for Commercial Laundries

Leverage a tool built for laundries and the types of equipment you have in your plant.

- Reduce unplanned equipment downtime

- Extend longevity of equipment

- View all your maintenance tasks in one place, with no need to track maintenance tasks in Excel spreadsheets or on paper

- Built for laundries

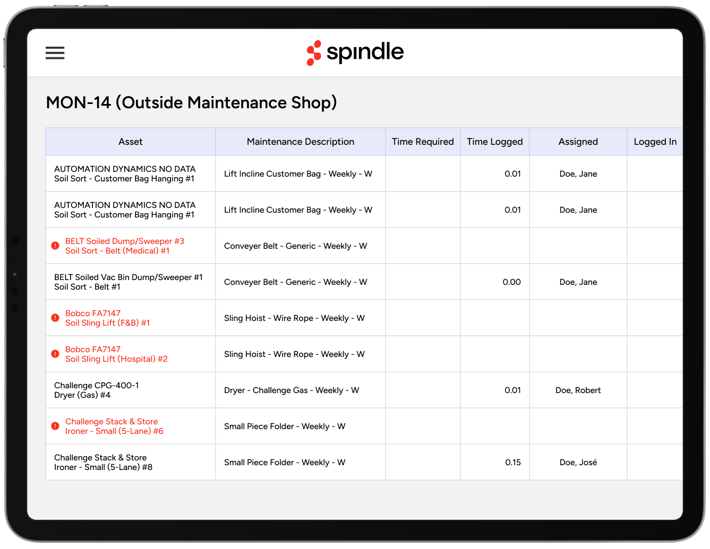

Everything You Need in One Place

Real-time, automated data collection converges in one place so you can see what’s happening with any piece of equipment at any time. Equipment status, who’s working on it, downtime, maintenance history, part inventory and much more: it's all there.

To a plant manager or engineer, CMMS is like having an extra set of eyes on each piece of equipment, 24/7.

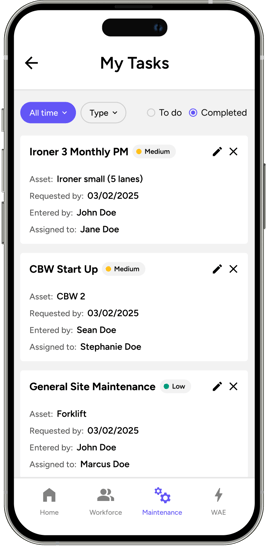

Your Daily Tasks. Right on Your Phone.

View your scheduled maintenance tasks right from your phone. No clipboards, no back-and-forth.

Spindle CMMS puts daily PMs, work orders, and equipment details in the palm of your hand, so technicians can stay on track, respond faster, and keep everything running smoothly.

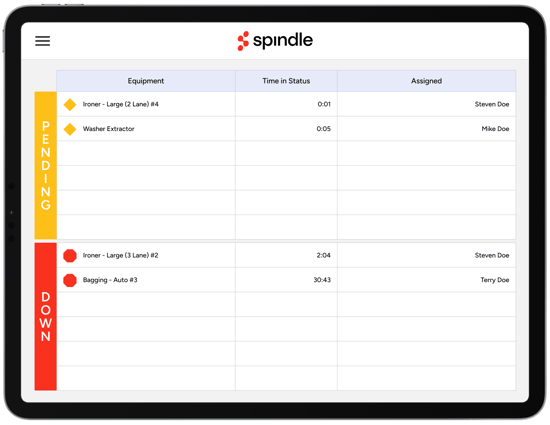

Track and Improve Response Times

Spindle CMMS tracks response times, active work orders, and the status of every asset in real time. See how long it takes to respond to issues, which technicians are working on which equipment, and how long each task is taking.

Turn maintenance speed into insight.

Features

Schedule and Track Preventive Maintenance

Get ahead of equipment failure before it strikes and throws a wrench into your production plans. Schedule preventive maintenance to keep your equipment in tip-top shape.

Work order management

Keep tabs on all the maintenance work going on in your plant.

Quick Maintenance

Allow for a 2-minute period for production staff to clear jams, replace bags and other quick maintenance tasks.

Real-time reporting

Get constant updates about your equipment and identify trends that can help you identify problem areas more quickly.

Maintenance History

Instantly see all the work that has been done on any equipment asset.

Labor Time Tracking

Track actual labor time versus scheduled labor time.

Parts inventory management

Be aware of what you do and don’t have on hand so you can be ready for future needs and restock if necessary.

Customized reports

Make the data work for you. Run customized reports to display data and KPIs that matter most to you.

Programmable preventive maintenance library

You don’t need to reinvent the wheel every time you do maintenance. Store all of your preventive maintenance procedures in one place so there are no knowledge transfer concerns when going from technician to another.

The Leading Laundries Select Spindle for Their Operations Platform

0

+

Customers

0

+

Countries

0

+

Pieces of Equipment Connected to Spindle

0

+

Employees Real-time Feedback Everyday

Hear from Our Customers

“The ongoing monitoring by Spindle and regular feedback with actionable information is what sets them apart.”

“The PPOH improvement has exceeded our expectations, but more importantly our employees can feel what success feels like because of the real-time feedback and that is priceless.”

“It is the most invaluable piece of equipment you can install into your plant.”

Ready to Take Control of Your Equipment’s Fate?

Forget about hoping and praying your equipment will continue running or that you’ll avoid unplanned downtime. Take matters into your own hands and be proactive about your equipment maintenance.