How Plant Managers Get More Done in Less Time

Labor is tight. Expectations are high. And every shift brings new challenges: missed goals, equipment issues, absenteeism, and endless fire drills.

Spindle helps Plant Managers take control. With real-time visibility, performance benchmarks, and prioritized next steps, you’ll know where to focus, how your team is doing, and what to fix next.

No more guessing. Just actionable data, AI-powered insights, and proven robotics solutions that help you lead your plant to new levels of productivity, accountability, and consistency.

Give Your Team a Clear Path to Laundry Excellence

Spindle’s Facility Health Score turns complex plant data into a simple, actionable score so your team knows exactly where to focus and how to improve.

Instead of reacting to issues, empower your managers with real-time visibility and prioritized next steps that drive results across productivity, maintenance, and equipment performance. Track all of your plant's KPIs and data trends, all in one place.

.png?width=2000&name=Spindle_Workforce-Facility-Health-Data_Product-Images%20(1).png)

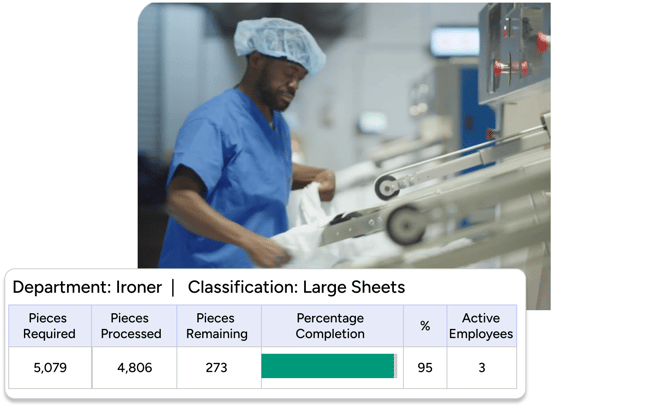

Automated Data Helps You React Faster

We know you have a lot to keep track of and you only have so much time in the day. Forget about spending hours on data collection – automated data collection frees you up to focus on bigger-picture things, like your employees, your plant’s overall efficiency and overcoming the various challenges that can pop up on any given workday.

Stop Equipment Downtime By Leveling Up Your Maintenance Program

Unplanned downtime due to equipment failure is incredibly disruptive and expensive.

With Spindle CMMS, you’re always in the know about your equipment’s maintenance status and schedule. That way, you can proactively say goodbye to equipment failure surprises.

Make Your Data Your Competitive Advantage

Unlocking the potential of AI in your plant starts with the right foundation: real-time, reliable data from every corner of your operation. That’s where Spindle comes in.

Built from inside the laundry industry, our platform already understands the nuances of your workflows—your tunnel loads, press times, equipment patterns, and production variability. We speak laundry because we were raised in it.

Today, we help operators like you make sense of the data you already have, uncover new opportunities, and lay the groundwork for intelligent automation and AI that is actually custom fit for your plant.

Robots That Work Alongside Your Team

Hiring is tough. Staffing is unreliable. But the work still has to get done.

Robotics step in when labor falls short and never stray from the standard. Built to work alongside your team, they’re not replacing people. They’re elevating them. Empowering your workforce to focus on higher-value work while automation keeps the tedious, repetitive tasks moving.

By integrating robotics, you bring stability to your plant floor. Fewer variables. Fewer surprises. More confidence that every shift will run on time, every time.

Be Your Plant’s CMO: Chief Motivating Officer

We know employee engagement and retention can be major challenges for commercial laundries. Leveraging real-time data, you can see what’s working in your plant and what isn’t, down to individual employees. If an employee’s productivity is falling, you can quickly investigate why. Maybe it’s an equipment problem, or maybe it’s an opportunity for a coachable moment with your team member.

Data promotes an environment of transparency that you can use to engage in positive reinforcement with your employees and motivate them to be at their best.

The Leading Laundries Select Spindle for Their Operations Platform

0

+

Customers

0

+

Countries

0

+

Pieces of Equipment Connected to Spindle

0

+

Employees Real-time Feedback Everyday

Hear from Our Customers

“It helped the people who had the talent, because before they would look down the line and see team members not performing and wonder why they were working hard to make the numbers. Now, they know they’ll be rewarded for their hard work.”

“The PPOH improvement has exceeded our expectations, but more importantly our employees can feel what success feels like because of the real-time feedback, and that is priceless.”

"If you're looking for a CMMS solution, in my opinion Spindle has the best software available. We started using their CMMS program a few months ago and the tracking and information is top notch."

Develop tailored game plans to tackle your laundry’s specific challenges.

Every plant has its own unique set of challenges. As a plant manager, you need the tools to be able to tackle your plant’s biggest challenges, ultimately toward the goal of boosting productivity and finding cost savings. With Spindle, you can have all the tools you need to be the best head coach of your plant that you can be.