Laundry's Robot Integrator

Running a high-performing laundry operation is no small task. You’re constantly balancing efficiency, safety, and productivity—all while managing rising costs and a shrinking labor pool.

You need a solution that works as hard as you do. That’s where Spindle Robotics comes in. With deep experience across vendors and solutions, we help you choose the right fit, not just any fit.

Laundry's Leader in Robotic Solutions

With over 30 years in the laundry industry—and decades as both a system integrator and software developer—we combine deep, hands-on expertise with partnerships in robotics to deliver end-to-end automation solutions.

From initial consultation through seamless deployment and ongoing support, our proven track record and collaborations make us the trusted choice for bringing robotics to your plant.

Reimagine Your Production Floor

A modern laundry requires a modern workforce. That means a combination of human beings and robotics, working in tandem toward a single goal: reducing uncertainty on your plant floor.

By automating repetitive tasks in your plant, you can reduce human error and free people up to do higher-value work in your plant. Automation can help you take the fight to bottlenecks that hurt your productivity and slow everything down, particularly in the face of rising labor costs and labor shortages.

You never have to worry if the job is going to get done: head to the floor with certainty, every day.

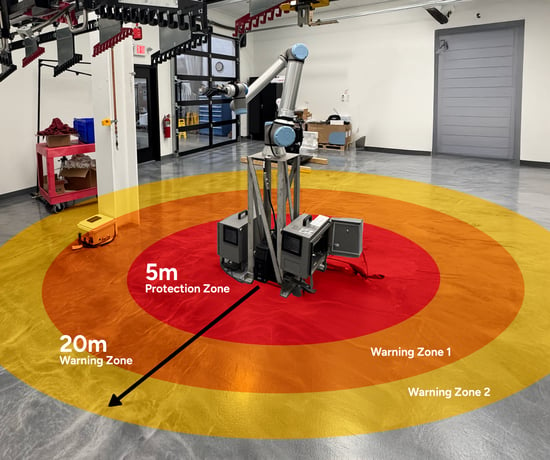

Safely Works Alongside Your Team

Spindle’s advanced cobots are designed to work safely alongside your workforce, taking on the repetitive, injury-prone tasks that slow teams down. By automating the right steps in your workflow, you not only boost reliability and output, but also create a safer work environment where your people can focus on higher-value tasks.

Our proprietary safety solutions meet OSHA technical bulletins so your team can work safely and efficiently.

Integrates with Your Existing Workflow

Integrate effortlessly into your existing plant infrastructure, delivering the power of automation without requiring changes to your plant’s footprint. Vendor-agnostic by design, Spindle works with your current machinery to enhance operations, not replace them.

We've Done the R&D So You Don't Have To

Our solutions aren’t picked off the shelf from a distributor. They're the result of rigorous research, development, and deep industry insight.

We’ve spent countless hours evaluating vendors, testing technologies, and working alongside laundries to ensure every product we deliver solves real-world challenges.

From sourcing the right end-effectors to integrating robotics with specific machine applications, we handle the complexity behind the scenes so you get a seamless, reliable solution that just works.

We're on a Mission to Solve Cloth Manipulation

The robotics landscape is evolving rapidly. At Spindle, we’ve invested in the resources to help the solve one of its most complex challenges: how robots interact with deformable objects.

Mastering this breakthrough is key to developing an adaptable, machine-agnostic approach to roboticizing laundry operations, ensuring seamless integration with existing equipment.

Proud industry member of Human Augmentation via Dexterity

Revolutionizing Robot Dexterity and Empowering Human Work

Explore the Spindle Robotics offerings

Hang to Hook

In Beta

Bring next-generation levels of efficiency to your laundry by automating one of the more repetitive tasks in the plant: hanging garments at soil sort. "Dolly" integrates into your existing infrastructure to streamline the sorting process and reduce strain on workers.

Smart Packout Conveyor

In Beta

Streamline material flow and eliminate hours of manual transport at packout. Designed specifically for the demands of commercial laundry operations, this solution helps operations build routes more efficiently.

Pick and Place

In Beta

The way laundries do repetitive material handling tasks has changed forever. Reliably transfer garments, linens, etc. from one station to another, such as from a sorting bin to a conveyor, or from a finishing machine to a folding or packing area.

Linen Feeder

In Development

We’re working with some of the world's top researchers to develop a versatile, machine-agnostic robot capable of feeding ironers by handling deformable objects like soft textiles, bringing precision to tasks that once relied on human touch.

Palletizer

In Beta

Our robotic palletizer automates the stacking of finished goods onto pallets, eliminating one of the most repetitive and physically demanding tasks in the plant. It ensures consistent load patterns, reduces risk of injury, and keeps pace with high-volume production lines.

Bag Filler

In Development

A robotic bag filler for mops, gloves, and similar items. It automates the manual process of placing items in bags, tying them by hand, and organizing them into carts—reducing repetitive strain and increasing throughput.

Spindle Robotics Integration Partners

Wherever you are in your automation journey, we're ready to help you take the next step.

Discovery Workshop

A Spindle representative will work with you to uncover the best opportunities around your plant.

Help With Implementation

Already have a solution in mind? With deep experience evaluating technologies, we help ensure it’s the right fit, not just any fit.

Trusted Tools, Ready to Go

Our solutions, backed by our expertise, are designed to get you up and running fast and ensure smooth implementation and impact from day one.

Hear from our customers

“I have been in the industry for many years. We have been using Spindle for over a year, and I can honestly say it's the best investment I have ever made in improving operations.”

“The PPOH improvement has exceeded our expectations, but more importantly our employees can feel what success feels like because of the real-time feedback and that is priceless.”

“It is the most invaluable piece of equipment you can install into your plant.”

Make Success Automatic

In the age of doing more with less, it’s never made more sense to explore the power of automation. With Spindle’s suite of productivity-enhancing automation products, you can realize success like you’ve never seen before.