Turn Your Manual Rail System Into a Smart Advantage

Your rail system is critical to your operation, but most offer little visibility. Spindle Rail modernizes your existing rail system without ripping and replacing.

By retrofitting your current setup with intelligent sensors, software, and automation, Spindle Rail transforms rail bottlenecks into orchestrated, real-time efficiency.

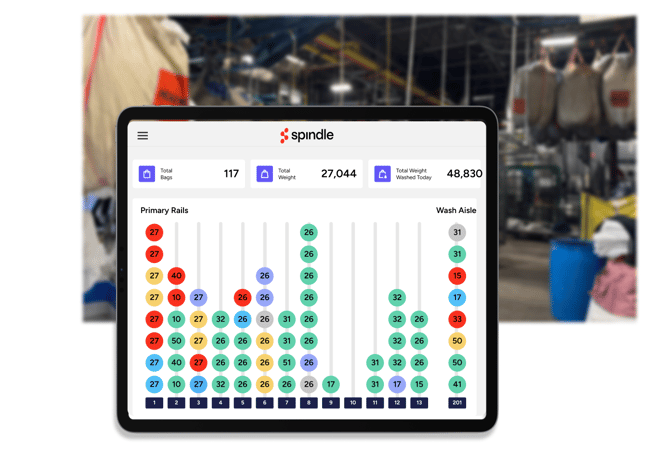

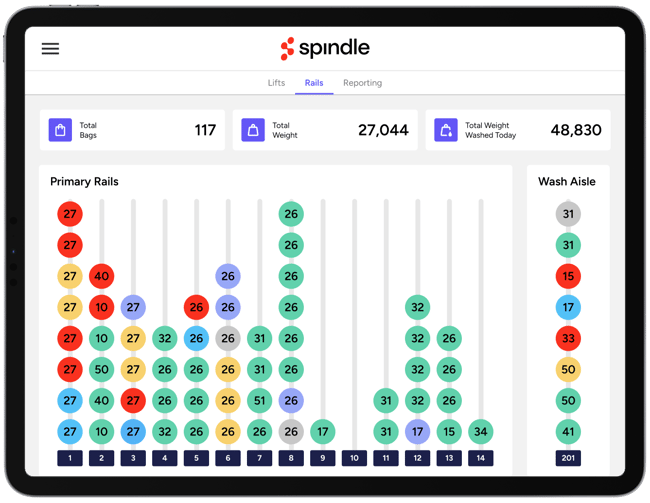

See Every Bag. Track Every Move.

Real-time insights into your rail system let operators and managers make informed decisions at every step. Know what’s waiting, what’s moving, and what’s next. No more guesswork, delays, or missing bags.

Remove the Guesswork.

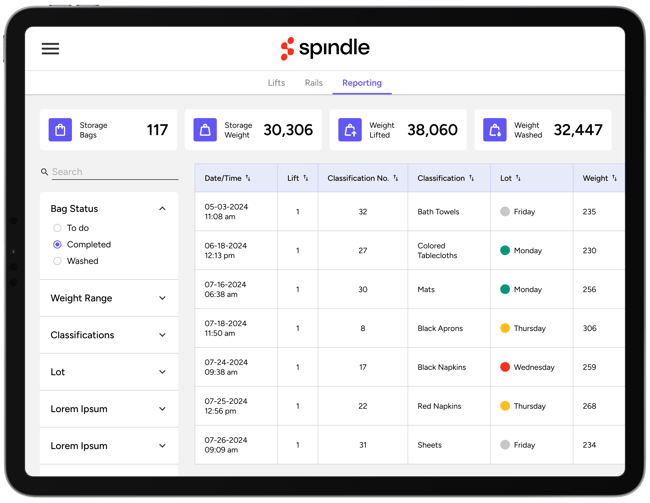

The Rail Reporting page gives you a clear, real-time snapshot of what’s happening on your rails, like how many bags are in storage, how much weight has been lifted or washed today, and more.

You can easily sort, filter, and group the data to spot trends, track performance, and make faster, more informed decisions about scheduling and inventory.

Make Smarter, Data-Driven Decisions Every Day

Plan Smarter on the Washfloor

Schedule wash cycles based on actual needs, not just assumptions.

Spindle Rail helps you prioritize by showing what’s hanging on the rails and what’s required next, so you can optimize wash floor sequencing and keep goods flowing efficiently.

Lower Linen Costs With Inventory Visibility

Avoid unnecessary linen purchases by knowing exactly what inventory is already on the floor.

Spindle Rail highlights products that have been hanging in soil for extended periods, helping you reduce overordering and get more from what you already own.

Track Pounds With Precision

Get accurate, automated weight tracking to support pounds-per-operator-hour (PPOH) metrics.

With reliable data on what’s moving through your plant, you can better assess performance, adjust staffing, and track trends over time.

Optimize Every Washer Load

Eliminate underloading and overloading. Spindle Rail integrates with scale data and applies theoretical wash load targets to ensure you're getting the most out of every wash cycle. Ultimately, that means boosting efficiency while protecting equipment and linen quality.

How Spindle Rail Works

Hear from Our Customers

“The ongoing monitoring by Spindle and regular feedback with actionable information is what sets them apart.”

“The PPOH improvement has exceeded our expectations, but more importantly our employees can feel what success feels like because of the real-time feedback and that is priceless.”

“It is the most invaluable piece of equipment you can install into your plant.”

Ready to Supercharge Your Rails?

Knowing what you’ve got on your rails is a must. How can you plan if you don’t? Learn more about how Spindle Rail can help you shed light on what’s going on up there on the rails.